Words by Hannah Reynolds

I’ve been wearing ASSOS shorts for twenty years, (not the same pair of course although I have a jersey from 2002 that is still in circulation) and in that time I’ve seen the range grow and become increasingly technical and sophisticated year on year.

ASSOS has always been a premium brand, its slogan ‘Sponsor yourself’ even acknowledges that buying ASSOS kit is an investment. Riders who have bought ASSOS have always done so in an understanding that it is a professional level garment for serious amateurs, at a serious price.

I have justified the expense to myself on a cost per wear basis, if my Windstopper bib-tights get worn every day throughout the winter, allowing me to continue to ride daily in even the coldest of weather then they are worth the £240 price tag. I just wish I could remember to apply the same logic to jeans.

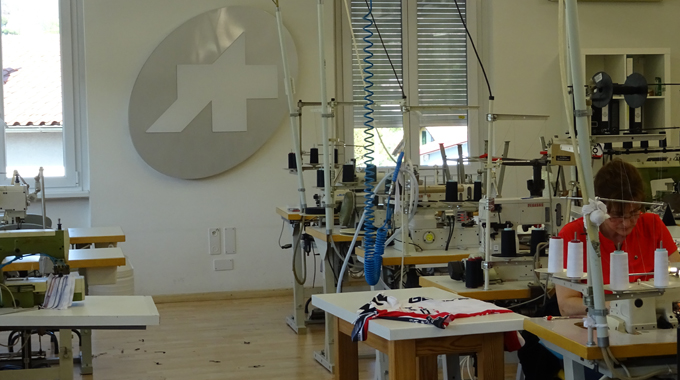

You know when kit feels good on and it performs well. That’s often reason enough to make it worth the money – whether it is an expensive or cheap garment. However, spending a day behind the scenes at the ASSOS factory in Switzerland made it abundantly apparent why it costs what it does. Desirée Bergman-Maier, daughter of the founder of the brand Toni Maier-Moussa , showed me around.