Inside the Brains of Hope

Who better to be my tour guide than Alan Weatherill. You may have seen Alan at trade shows and events, ready to answer all your Hope related questions, but Alan’s been with Hope Tech for 28 years. In fact, he was the 5th employee to be hired, and hasn’t looked back.

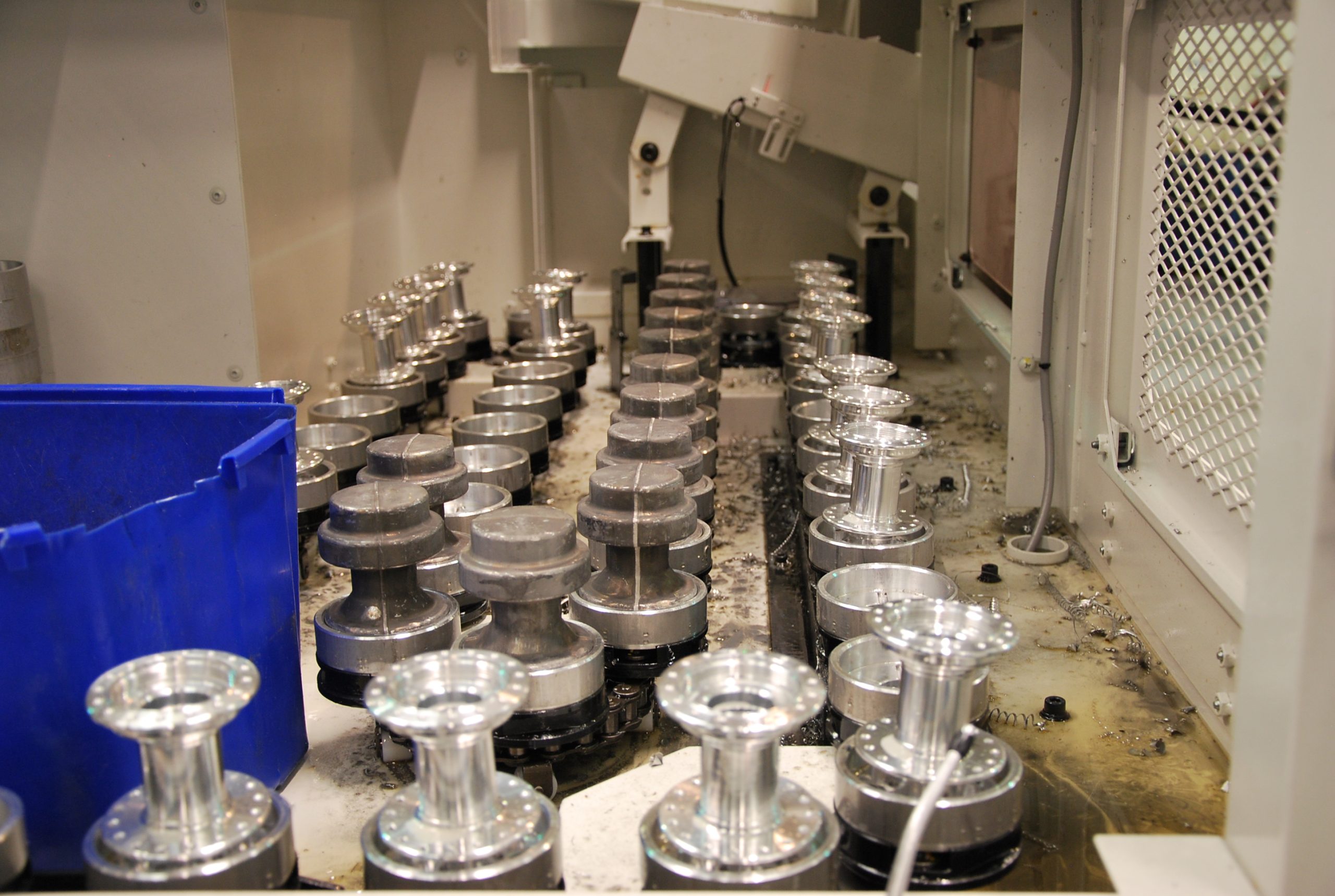

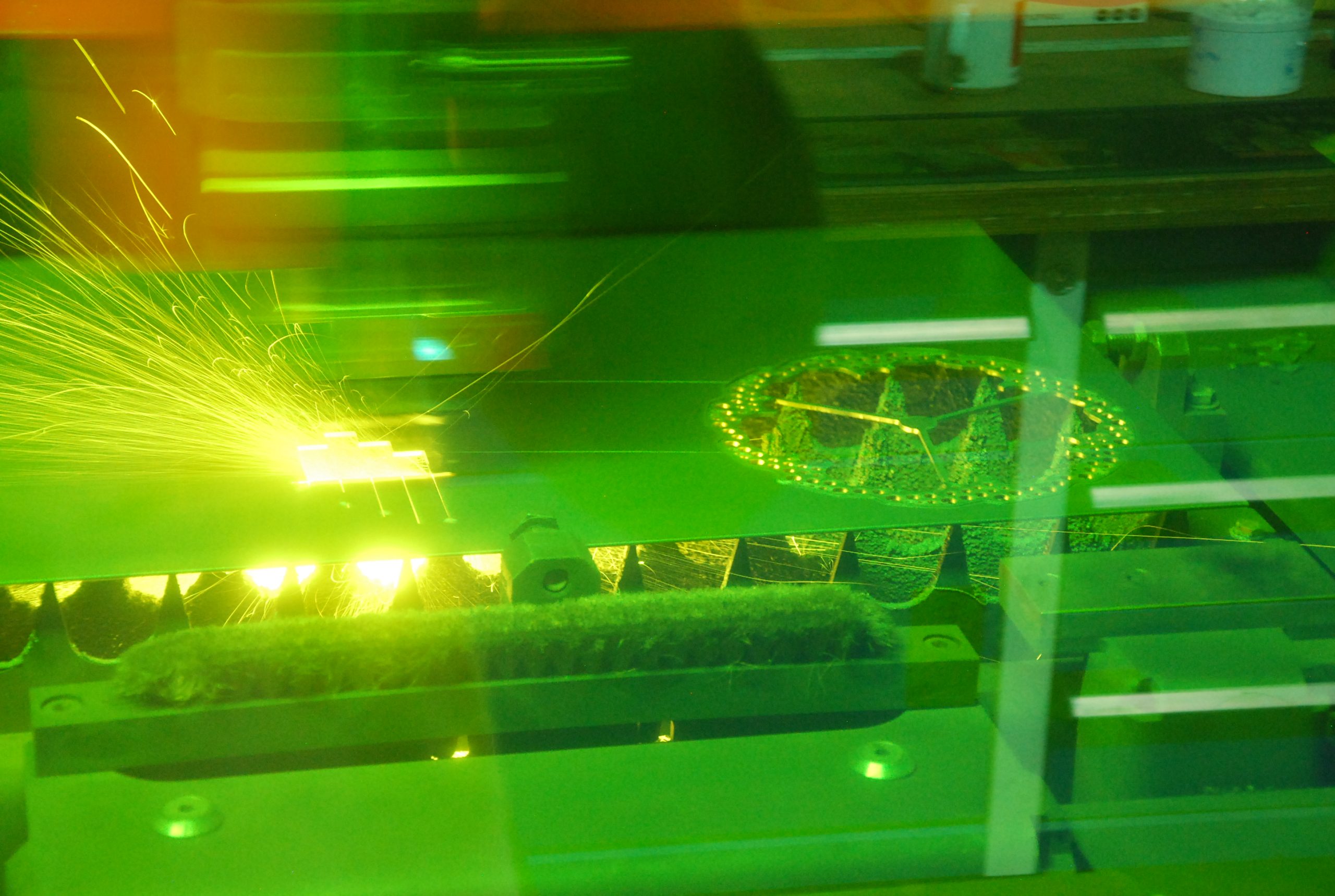

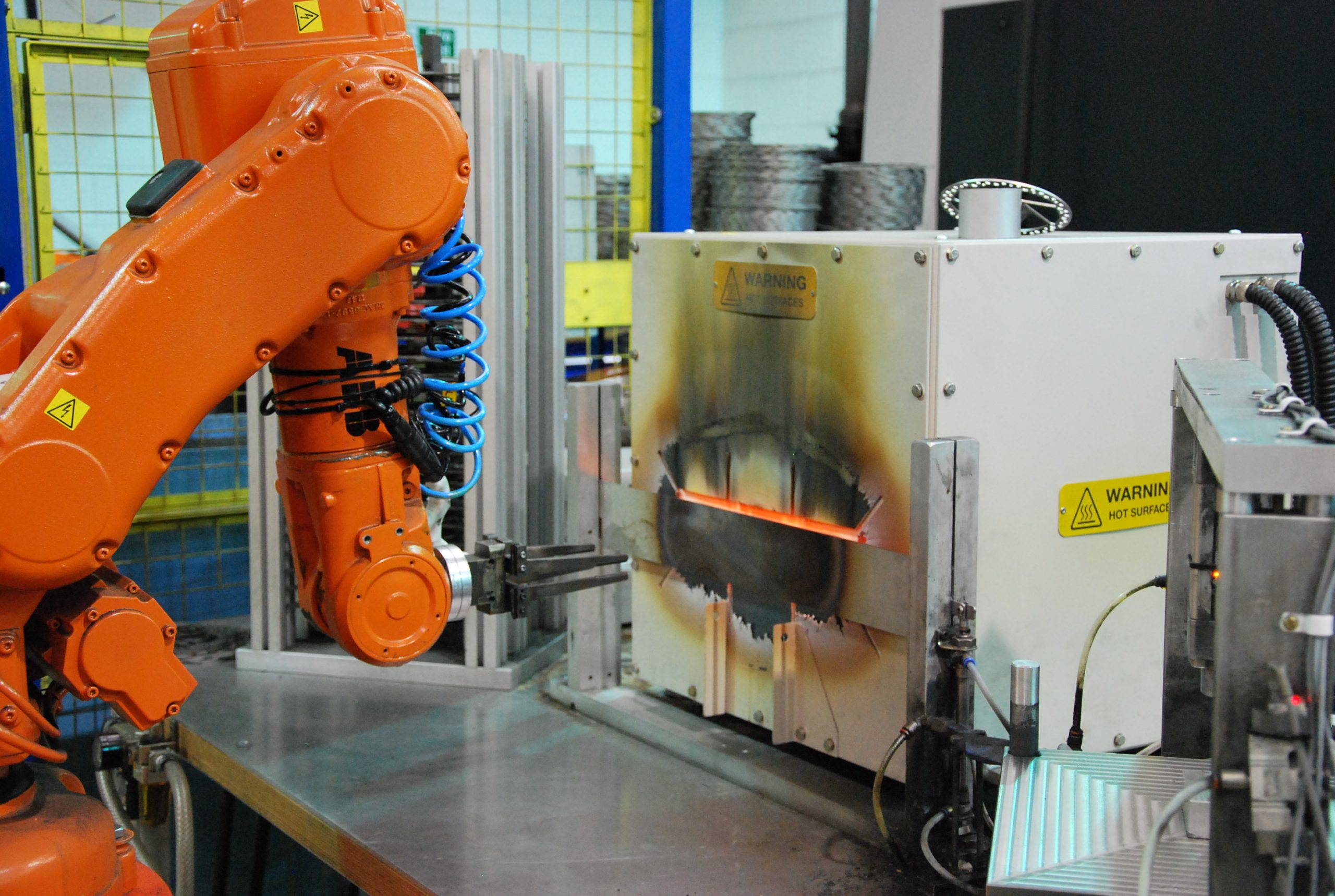

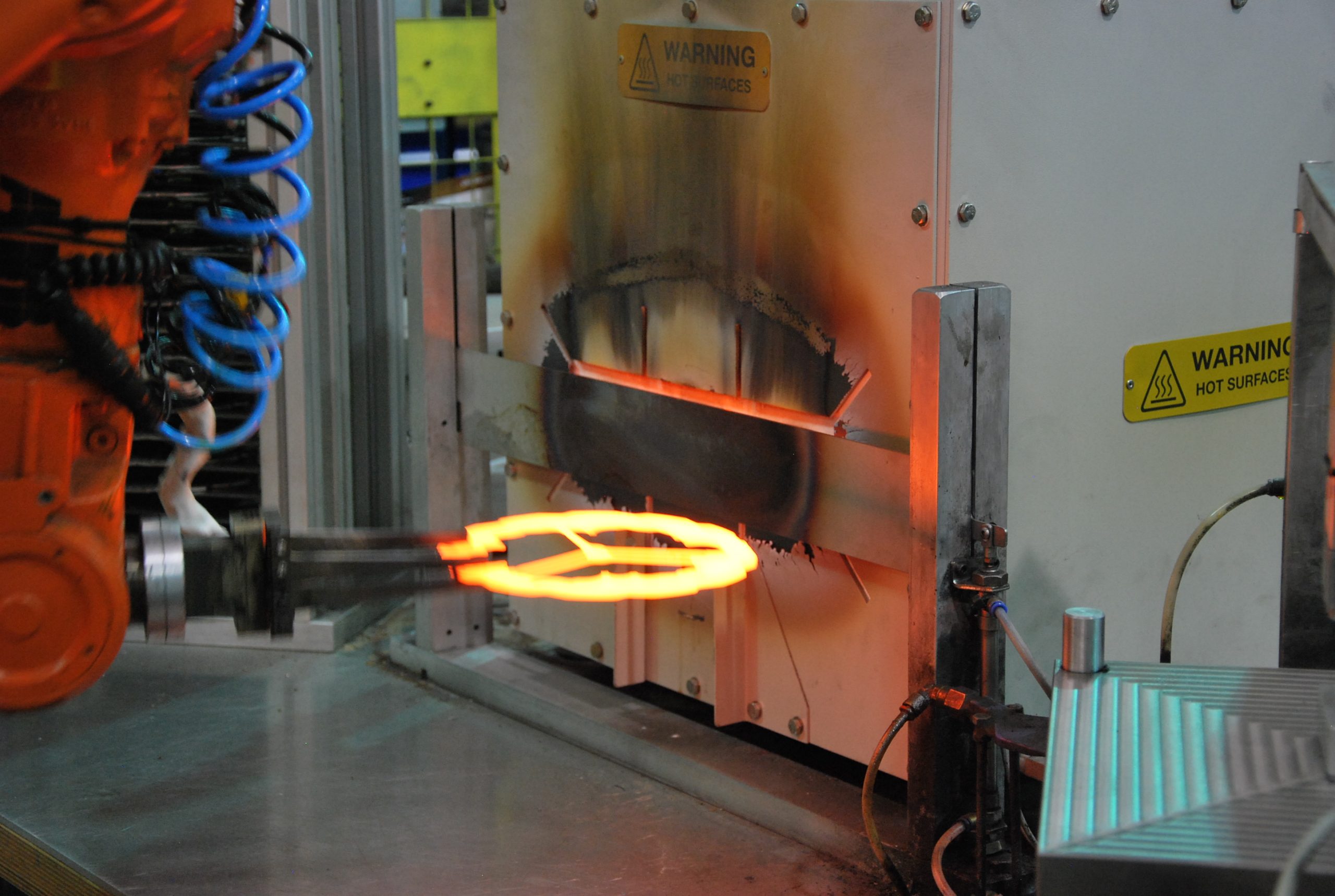

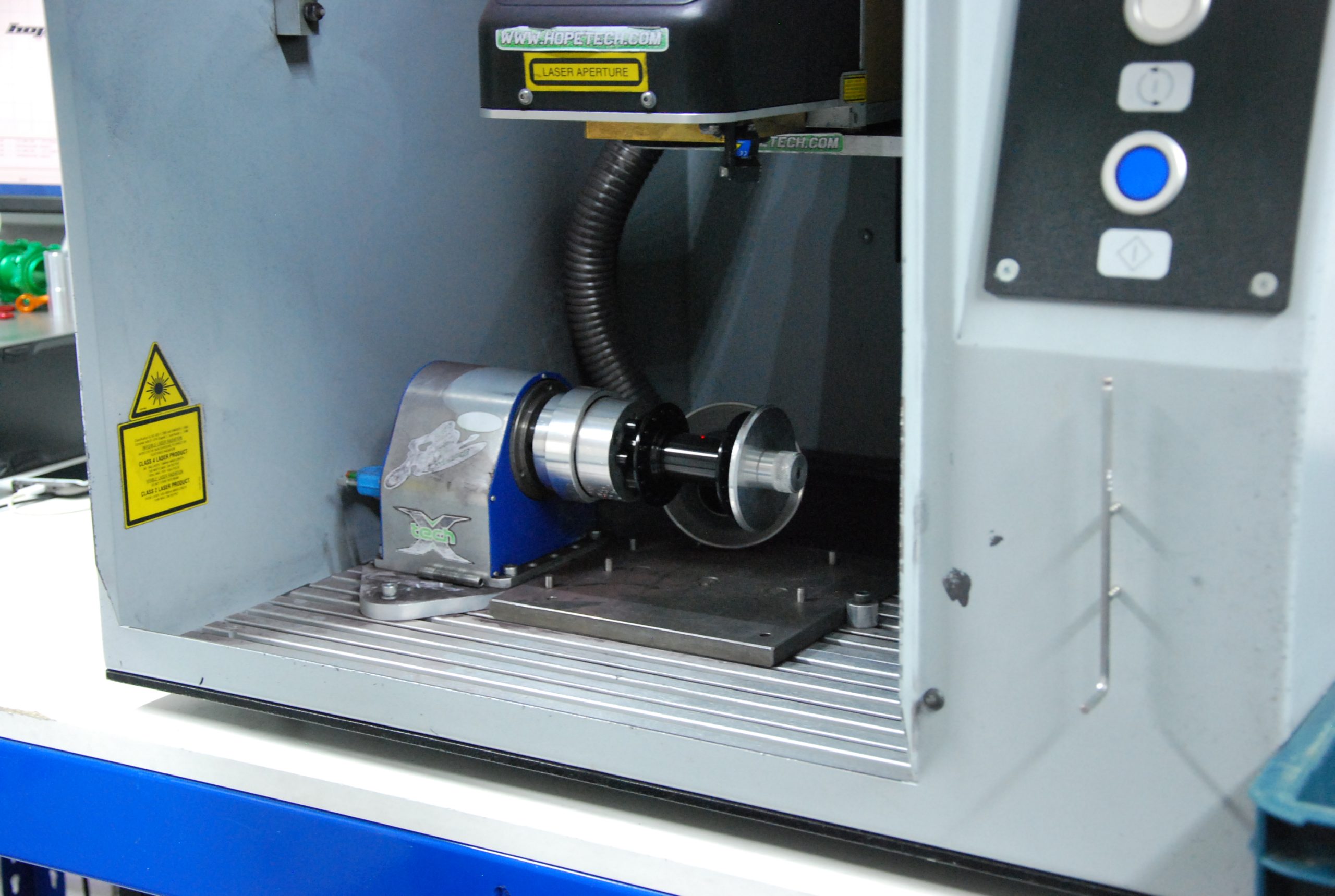

Alan showed me around each department and factory room explaining the process of machining components, and the absolute care taken on every part. Hope uniformed factory floor staff manned their stations, and diligently checked over every single piece that emerged from each machine.

Alan explained that “quality control is paramount for Hope. Every piece gets the once over by a member of staff, and batches are sent for quality control to test.” Stems, bars, pedals and hubs are put under extreme stress to assess breaking points and any defects in the products. The fact Hope takes such extra care with their quality process, having visual and mechanical assessments carried out, is just one reason Hope are where they are today.

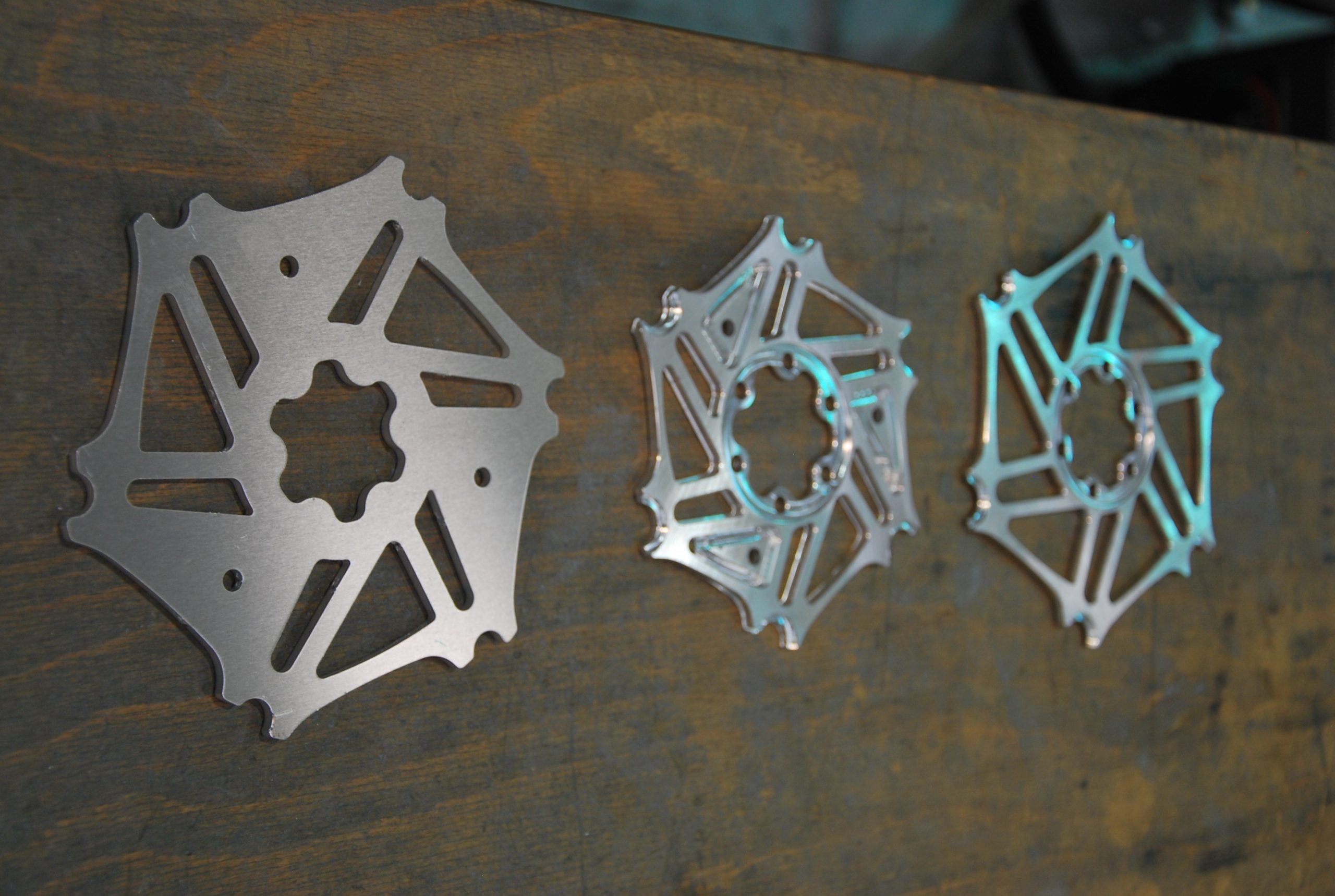

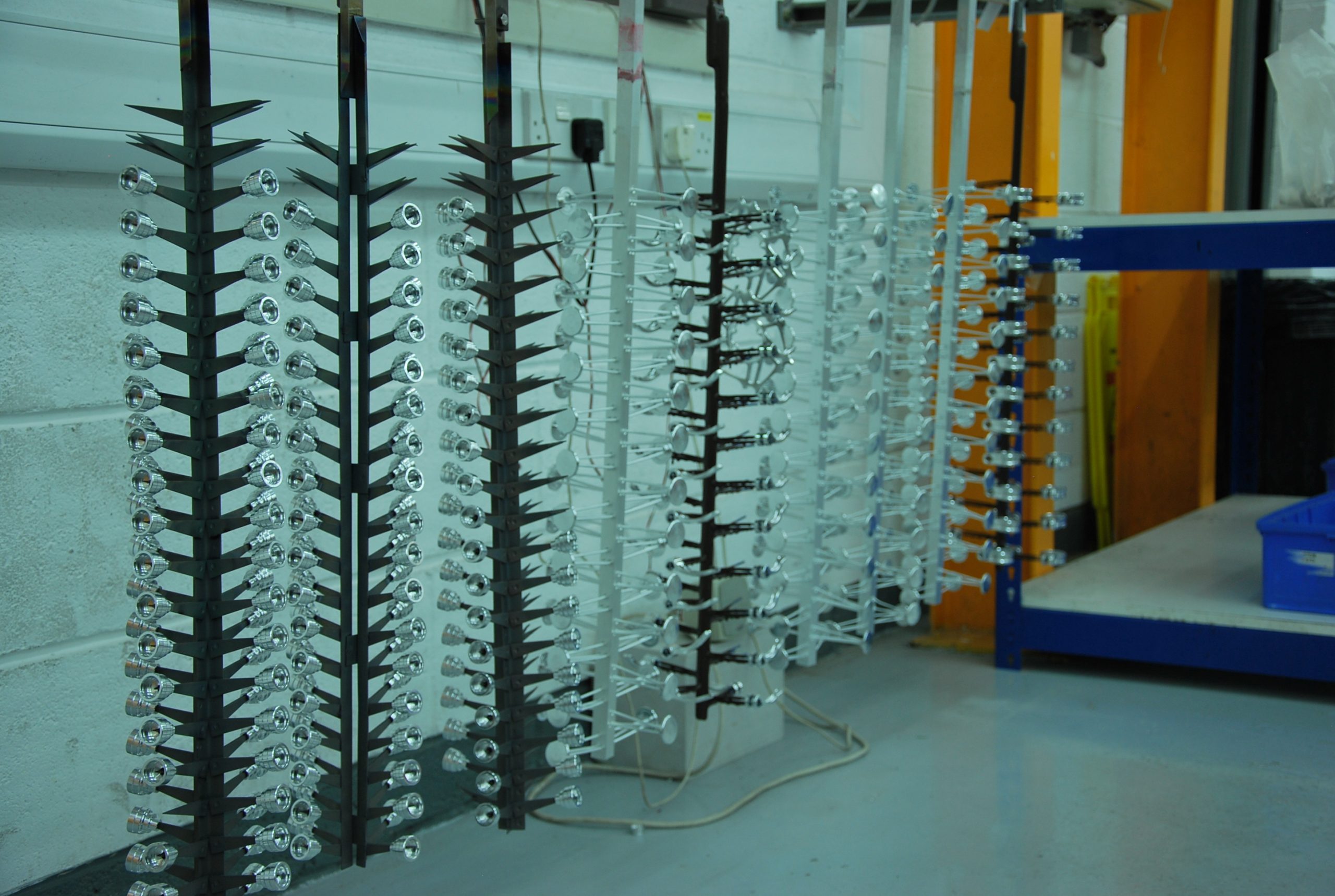

A majority of their components are available in 6 brilliantly anodized colours. When you consider that Hope has 5 stems available in different lengths and rises, and then to offer 6 colour choices… That’s a lot of permutations which many brands would avoid producing like the plague. But not Hope, they believe you should not only have the kit you need, but the option of having the kit you want to really personalise your ride.

When it comes to wheel building, Hope are one of the few to both machine and hand true the wheels. A trained member of staff with build the wheel, send it through a machine for an initial true, then it’ll be passed onto another member of staff to hand true for accuracy and precision.

After seeing all the hard working staff, the careful attention to detail and absolute pride taken in every component, it’s hard not to be blown away by Hope’s dedication to the cycling industry.

Without gushing too much about how amazing their factory is, and their staff, I also want to highlight their involvement in cycling outside of HQ. Earlier this year, Hope Tech Women launched which saw dozens of women meeting up, making friends and riding bikes.

Brand manager and avid rider, Rachael Walker is the driving force behind this movement and told me, “Even if we can get one more woman to take up cycling, I’m happy. We’re trying to break down the barriers that would usually prevent women from giving mountain biking a go.”

The staff are all wicked, friendly and seriously committed. I never got the vibe that I was wondering around an office or factory, it felt more like a home with employees considering one another as family.

Above all, Hope Tech cycling components are durable, functional and built with precision. They look pretty awesome as well! Check out the gallery below for the full insider access.