There’s nothing more more annoying than a rounded, or stripped, bolt. Common locations include seat posts, and cleats – common reactions include frustration and anger.

You know you’ve rounded, or stripped, a bolt when you insert an allen key, and rather than slotting in nicely, and turning, you’ll find the tool simply swivels in the bolt. Pieces of metal have been stripped away, so the key no longer fits the lock, so to speak. You might also notice tiny files of metal in the area.

If you’ve already rounded off a bolt – and are sitting next to your bike sweating for fear that you’re going to have to ride with your set too high/low for ever more, or buy some new cycling shoes because you can’t remove the cleats – don’t: there are ways to remove them.

We spoke to Jenni Gwiazdowski, Director at the London Bike Kitchen, to find out how she would go about removing a rounded bolt, and she gave us a couple of options:

- You can fill in the hole with super glue and stick something t-shaped into it, let it dry, and then use the handle to turn it out

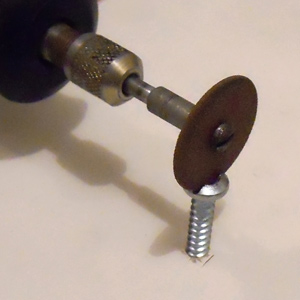

- Try cutting a slit into the bolt, and then sticking a flathead screwdriver into it – only do this if you feel confident, if not – ask a mechanic – regardless, the good news is that is very effective when done correctly:

- To do this you will need a Dremel Rotary Tool or a Hacksaw – just cut yourself a narrow slot, right across the middle of the bolt – effectively overriding the rounded hole in the centre…

- Then you’ll be able to simply slot a screwdriver into your new groove – snazzy!

-

Jenni also added that “sometimes you can just cut the bolt in half with a dremel, hacksaw or anglegrinder, or you can drill a hole into the bolt and drill it out in reverse” – we found a video demonstration of the latter but this is probably not best done by a mechanic who knows exactly what they’re doing.

Jenni did add: “this is a touchy, dangerous subject”. All these methods are very common and effective, but if you’re at all unsure, take your bike, or shoe, to see a mechanic – they will no doubt be able to help you, and failed attempts could make the problem worse.

How Not to Round Off Bolts in the First Place

We’ve put this second because no one in the situation above wants to be told how not to get there – but once you’ve sorted out your stuck bolt, there are a few ways you can prevent the problem happening again:

- Jenni’s top top was simple – be more careful when loosening or tightening bolts: “Make sure you use the correct sized tool for the bolt, and make sure it’s fitted in all the way into the bolt. Too often people only put in the tool halfway and then proceed to turn; there just isn’t enough traction here to make sure that the tool is fitting properly and it will slip, eventually rounding the bolt. Apply pressure both into the bolt, as well as in the turning direction, to ensure any slipping is minimised.”

- Multi-tools are great on the go – but use a proper allen/hex keys when you’re at home, the longer handle gives you better leverage

- Never overtighten bolts – seat posts, headsets and cleats usually have written on them (or with their accompanying instructions or owners handbook) a recommended torque – this is written in ‘newton metres’ – such as 5Nm or 10Nm. In an ideal world, you’d use a torque wrench to ensure you get the right tightness, but if you don’t have one, ask someone to show you how tight it should be, and after some practice you’ll learn the ‘feel’ or 5 or 10Nm.

- Cleat bolts can be a real pain – the metal is often very soft, so they round very easily. Keep them clean, don’t walk too much off the bike (or use the cleat covers that no one ever uses…) and avoid muddy, gritty surfaces – this helps to keep them in better condition, which makes removal easier.

You might also like…